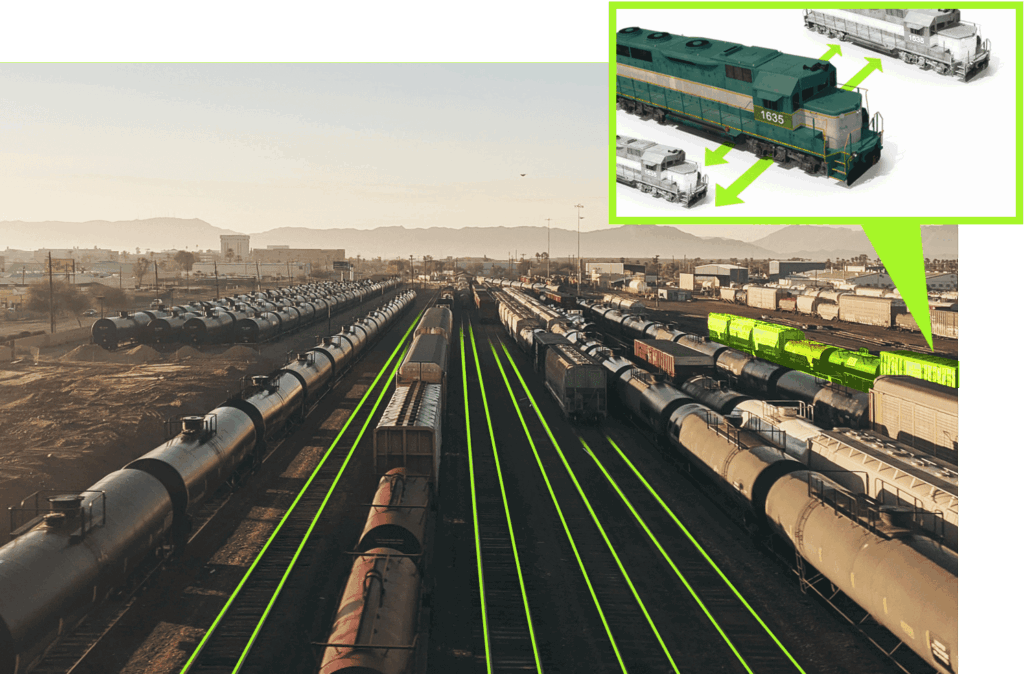

Railspire retrofits customer locomotives for up to SAE level 4 autonomous driving, with an initial focus on yard, near-yard, and industrial environments.

AI-POWERED

AUTONOMOUS LOCOMOTIVES

FOR RAIL YARDS & INDUSTRIES

Your Locomotives

Our Software

Autonomy, up to SAE Level 4

Human-Led, AI-Enhanced Operations

Open Platform for Integrations

Safe, Efficient, and Precise Rail Operations

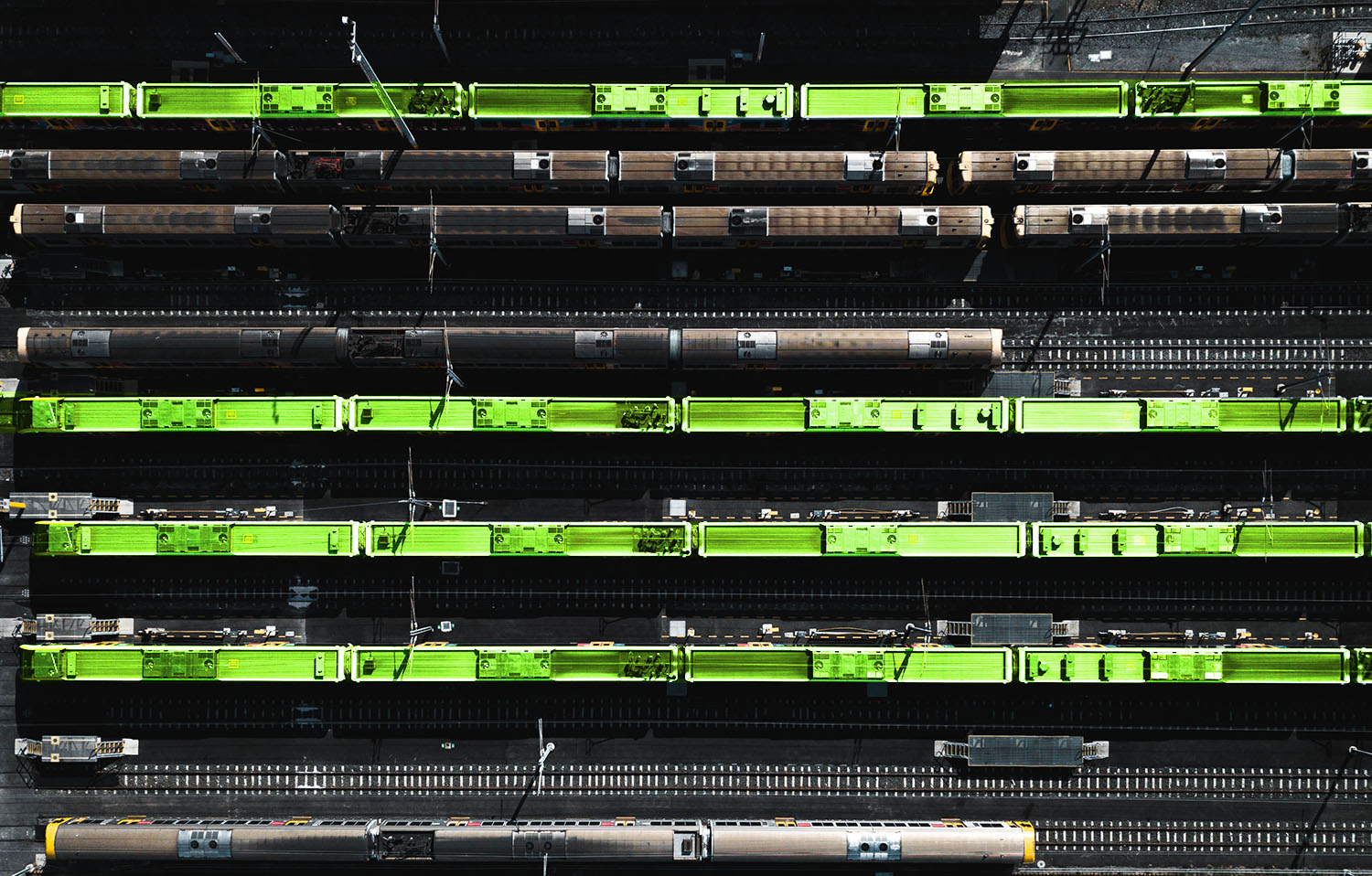

Our locomotive autonomy is built to enhance safety, increase productivity, improve worker retention, and reduce damage.

Increased Situational Awareness and Safety

Railspire relieves operators of train handling micro details, allowing them to better focus on their surroundings, such as the locations of fellow workers and of other nearby trains. This improved situational awareness helps enhance safety for all employees.

Railspire’s artificial intelligence software has precision driving abilities that far exceed human capabilities. Railspire can also integrate with adjacent technologies and assets. Combined, these capabilities reduce human factor errors, the leading cause of train accidents (37%).

Increased Productivity

Railspire-equipped, autonomous locomotives allow for dramatic increases in productivity by increasing yard throughput and cars per labor hour, and lowering railcar dwell.

Improved Retention With a Safer and More Comfortable Work Environment

Railspire operators can work in safer, climate-controlled, and even remote locations. Those improved work environments make for more desirable job positions and help the company recruit and retain the best talent.

Railspire simplifies complex railroading tasks and thereby allows customers to accomplish the same work with lower cost labor, with less training and recertification and more geographic and skillset flexibility.

Reduced Asset and Cargo Damage

Software-control of locomotive tractive effort and braking, in response to variables such as grade, slip, tonnage, length, provides consistently precise train movements that reduce asset wear and tear and cargo damage.